FAQ Customer Care

The Inoxbim Customer Care office is at the disposal of anyone who has encountered faults or malfunctioning during use of our cooking, refrigeration and transformation equipment. Here below you will find the most frequently asked questions about problems during use in the kitchen. Our answers are meant to help you resolve the functionality of the Inoxbim and MacChef problems totally on your own and in a short time. IMPORTANT: If the problem persists after reading our FAQs: Fill in the Assistance form and an operator will reply as quickly as possible. To make our intervention easier, you will be asked to provide us with:

- the model of your equipment;

- the retailer where you purchased it;

If urgent, please personally contact your technician and provide them with the same information. You will find this information on the documents you received when you purchased our product.

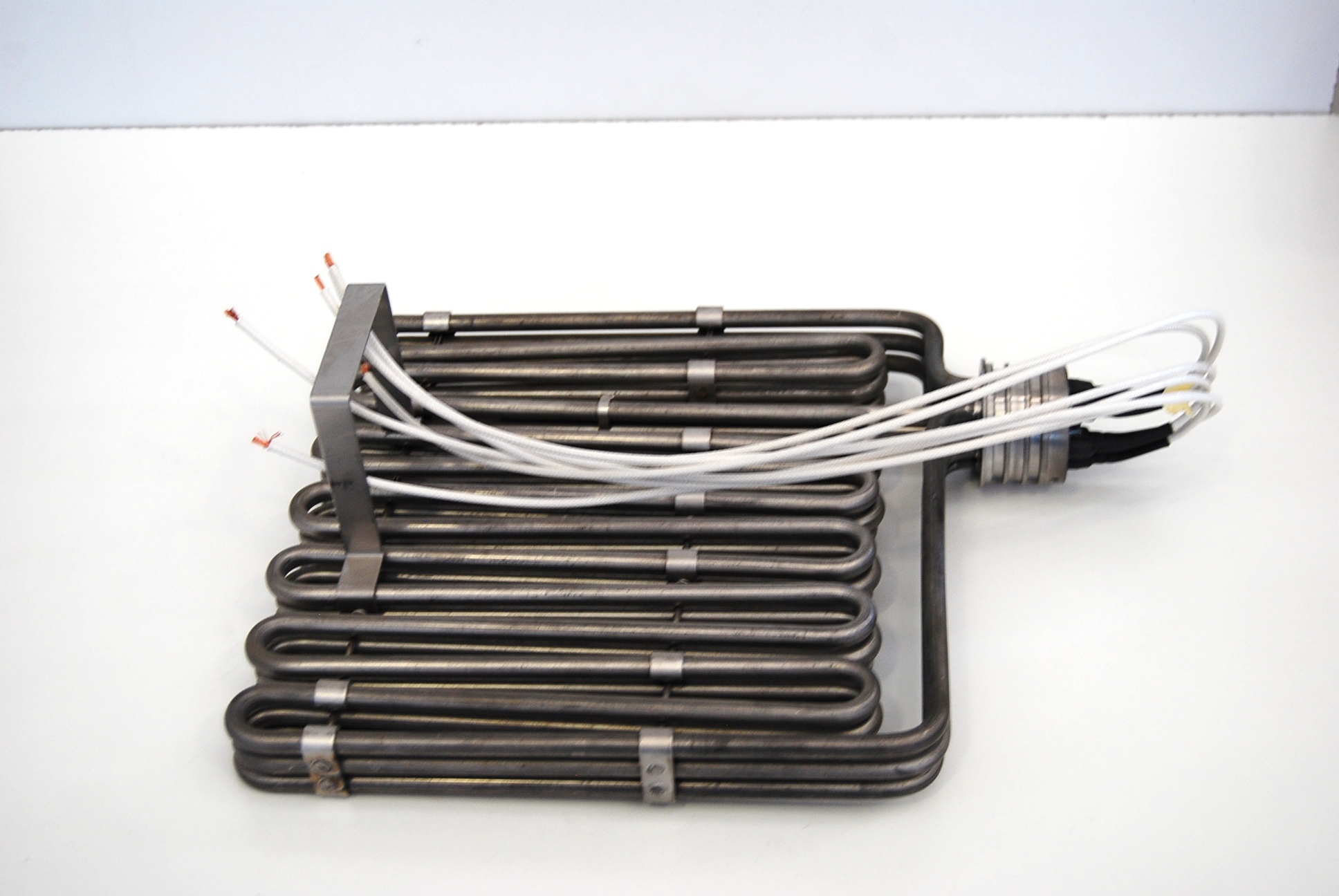

One of the most likely causes concerns ice forming around the evaporator.

Read the Synthetic User Manual and follow the procedure to start defrosting.

Carry out this operation with the doors open and before each blast chilling/freezing cycle.

The blast chiller has been switched off for a long time and has lost its memory.

Read the Synthetic User Manual and follow the procedures to set the date and time on the display.

These alarms are related to failures or disconnections of the internal sensors, specifically:

- alarm PR1 indicates a cell sensor error;

- alarm PR2 indicates a pin sensor error;

- alarm PR3 indicates an evaporator sensor error.

In this case notify the alarm code to your technician in order to solve the problem as soon as possible.

The most probable causes concern inserting products with a higher temperature than the holding temperature, or the possible wear of the seals.

Check seal wear

- check that the doors close properly;

- in case of damage or wear, contact a technician for their replacement;

Should the problem persist even after these tips, contact a technician.

The most probable causes concern ice forming around the evaporator, or inserting products with a higher temperature than the holding temperature.

Check that the evaporator is working properly

- The evaporator is located inside the motor unit, under the polystyrene cover;

- check the correct temperature on the counter’s electronic display:

- press the SET button once;

- press the “ARROW” button in the upper left corner twice to make PB2 appear;

- press the SET button once and read the evaporator temperature;

- the evaporator temperature must be 6-7 °C lower than the temperature of the refrigerating compartment;

- should the difference be greater, ice has formed around the evaporator.

- In this case, switch off the freezer counter, remove the food, leave it open for 24 hours and follow your HACCP cleaning procedures before turning it on again.

Should the problem persist even after these tips, contact a technician.

The most probable causes concern the frequent and prolonged opening of the doors of the freezer cabinets, or a possible wear of the seals.

Checking seal wear:

- check that the doors close properly;

- in case of damage or wear, contact a technician for their replacement;

Upright freezer defrosting:

- press the “arrow” button in the upper left corner of the electronic display of the cabinet;

- Check on the display that the automatic defrost indicator lights up.

- Except for the special cases indicated in your HACCP procedures, it is possible to leave the food inside the freezer during defrosting

Should the problem persist even after these tips, contact a technician.

One of the most probable causes is the malfunction of the safety thermostat.

Reactivating the safety thermostat:

- open the lower compartment of the gas pasta cooker;

- the safety thermostat is located behind the door;

- press the red button on the thermostat;

- if you hear a click, the thermostat has been reset;

- if you don’t hear anything, that’s not the problem.

Should the problem persist even after these tips, contact a technician.

The most probable causes concern the incorrect position of the resistance and the malfunction of the safety thermostat.

Correct position of the resistance inside the pan:

- Turn off the fryer;

- make sure the temperature of the resistance is not too hot before holding it;

- make sure that the resistance is lowered until it is parallel with the bottom of the pan;

- switch the fryer back on;

Reactivating the safety thermostat:

- Open the lower compartment of the fryer;

- the safety thermostat is located behind the door;

- press the red button on the thermostat;

- if you hear a click, the thermostat has been reset;

- if you don’t hear anything, that’s not the problem.

Should the problem persist even after these tips, contact a technician.

The most probable causes concern the cleanliness of the pilot nozzle and the integrity of the thermocouple sensor.

Pilot nozzle cleaning:

- remove the nozzle with a hexagonal spanner (the size depends on the type of nozzle);

- blow on the hole of the nozzle with compressed air to remove any possible obstruction;

- reassemble the nozzle.

Thermocouple sensor check:

- it is positioned next to the pilot flame;

- check that it is not cracked, broken, or damaged;

- should you find one of these problems, contact the technician for its replacement;

Should the problem persist even after these tips, contact a technician.

Assistance form

An operator will reply as quickly as possible

If urgent, please personally contact your technician.